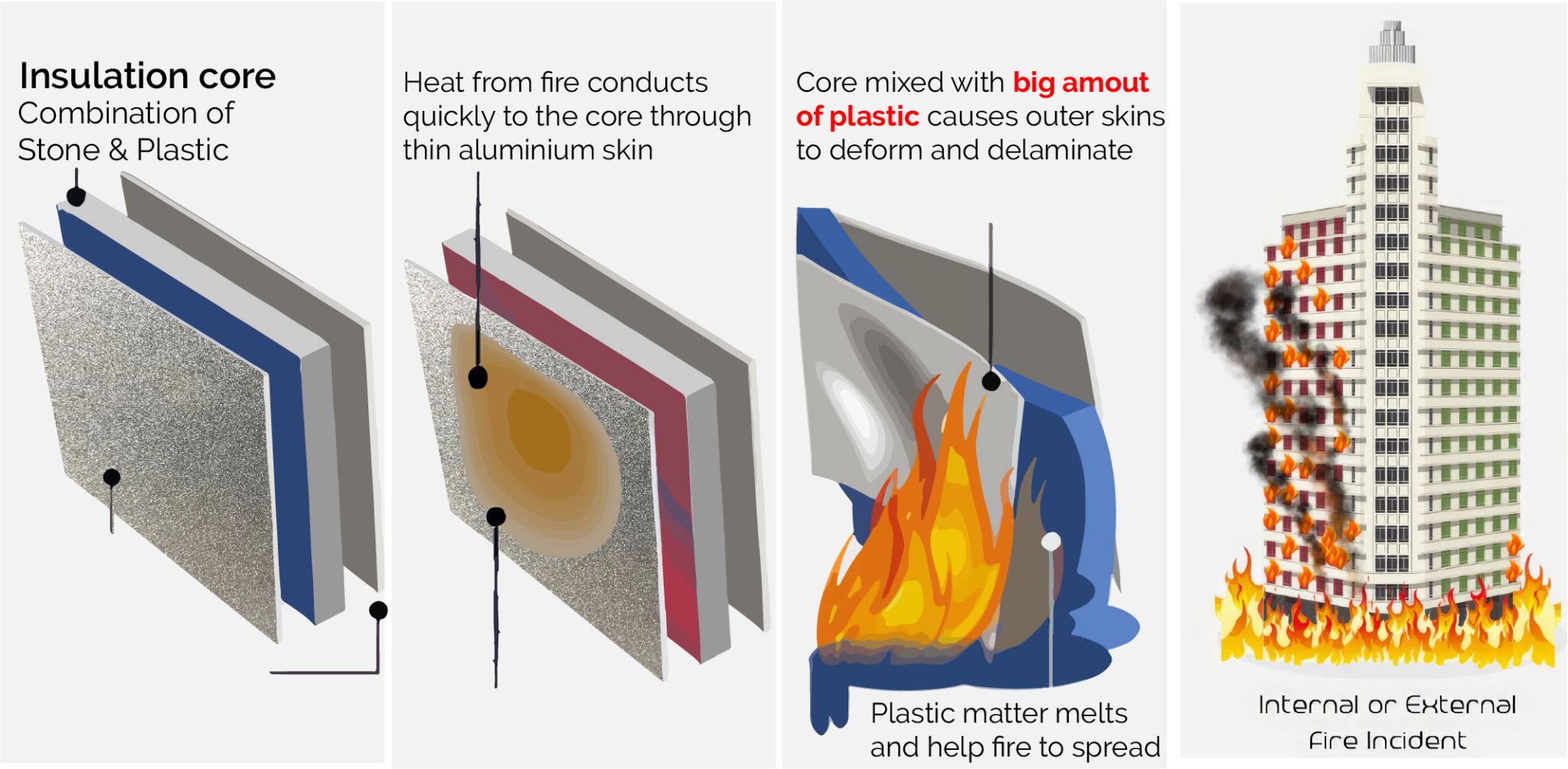

Aluminum Composite Panels (ACP) are widely used in modern construction due to their versatility and aesthetics. However, not all ACPs are created equal, particularly when it comes to fire resistance. Unfortunately, some manufacturers sell panels labeled as Fire-Resistant (FR), while their cores are laden with excessive plastic, significantly compromising fire safety. The stakes of using substandard ACP panels are immense, with the potential to result in catastrophic fires that risk lives and property. As a buyer or specifier, you must be vigilant and well-informed to ensure the safety of your buildings.

The Risks of Substandard ACP Panels

One of the most dangerous issues in construction today is the use of

ACP panels with high plastic content in the core, despite being labeled as fire-resistant. The core of genuine FR panels is typically composed of mineral materials designed to retard the spread of fire. On the other hand, panels with polyethylene (PE) or other plastic-filled cores can accelerate the spread of fire, creating a hazardous situation in which flames move rapidly up the building's exterior.

In some instances, manufacturers intentionally mislabel panels as fire-resistant to cut costs, compromising safety in the process. This issue has led to major fire incidents around the world, with tragic consequences. The Grenfell Tower fire in London is perhaps the most infamous example of what can happen when non-compliant ACP panels are used.

The Grenfell Tower Fire: A Tragic Reminder

On June 14, 2017, a fire broke out in a high-rise residential building in West London, known as Grenfell Tower. The fire quickly escalated, engulfing the building’s facade and spreading rapidly due to the use of ACP panels with a flammable polyethylene core. The result was a disaster that claimed 72 lives and left many more injured. The investigation into the incident revealed that the ACP panels used on the tower’s exterior did not meet fire safety regulations and were a key factor in the rapid spread of the fire.

The Grenfell Tower tragedy could have been prevented if proper fire-resistant materials had been used in compliance with safety standards. The building’s cladding failed to meet critical fire safety tests, and the panels did not have the proper third-party certification to verify their fire-resistant qualities. This event highlighted the dangers of using ACP panels with high plastic content in their cores and led to a global reconsideration of fire safety standards in building materials.

The Catford Fire: Another Wake-Up Call

In 2007, the Catford fire in southeast London further illustrated the dangers of ACP panels with inadequate fire resistance. This incident occurred in a building clad with ACP panels containing polyethylene cores. Like Grenfell, the fire spread rapidly along the building’s exterior, prompting evacuation and emergency responses.

While the Catford fire was less deadly than the Grenfell Tower tragedy, it served as an early warning about the risks associated with non-compliant

ACP Cladding materials. Unfortunately, not enough action was taken in response to prevent the later Grenfell disaster. The lessons learned from Catford reinforce the need for strict adherence to fire safety standards and proper testing of ACP panels used in construction.

Preventing Future Disasters: How to Ensure Genuine Fire-Resistant ACP Panels

In light of these tragedies, it is crucial for buyers and specifiers to take proactive steps to ensure the ACP panels they purchase are genuinely fire-resistant. Here’s how you can protect your building from fire hazards and prevent incidents like Grenfell and Catford:

1. Always Request Third-Party Certification

One of the most effective ways to ensure you are purchasing truly fire-resistant ACP panels is by requesting third-party certification. Reliable manufacturers will provide documentation that verifies their products comply with recognized fire safety standards.

For instance, ASTM D1929 is a widely recognized standard that requires the ignition temperature of the core material to be above 343°C. If a product does not meet this standard, it may contain high levels of plastic, making it more flammable. Additionally, testing should confirm compliance with other fire safety standards, such as EN 13501-1.

2. Look for EN 13501-1 Compliance

The most critical fire safety standard to look for in ACP panels is EN 13501-1, which is used to classify the fire performance of building materials. To ensure maximum fire resistance, ACP panels should achieve Euroclass B-s1,d0 under this standard.

Euroclass B-s1,d0 is the highest level of fire resistance achievable for ACP panels, meaning that the panels will contribute minimally to fire spread, produce limited smoke, and release no flaming droplets or particles. If a product fails to meet this classification, it likely contains excessive plastic, putting your building at risk of rapid fire spread.

3. Avoid ACP Panels with High Plastic Content

To ensure fire resistance, avoid ACP panels with a high percentage of polyethylene or other plastic materials in the core. These materials are highly flammable and can contribute to the rapid spread of fire in the event of an outbreak. Panels with mineral-filled cores offer superior fire resistance and are specifically designed to prevent fire escalation.

4. Understand the Long-Term Risks of Using Non-Compliant Panels

Using non-compliant ACP panels may save costs upfront, but it can have devastating consequences in the long run. Not only do substandard panels increase the risk of fire, but they also expose building owners and contractors to legal liabilities and expensive retrofits.

After the Grenfell fire, hundreds of buildings across the UK were found to have non-compliant cladding, leading to a massive and costly effort to replace the panels. The financial and human costs of using unsafe materials far outweigh any potential savings during construction.

Final Thoughts: Prioritize Fire Safety in Construction

The Grenfell Tower and Catford fires were both stark reminders of the dangers posed by ACP panels with substandard cores. The tragedies could have been prevented if proper fire-resistant materials had been used, and if buyers and specifiers had ensured compliance with critical safety standards.

To prevent future disasters, always insist on third-party certification, verify compliance with standards like EN 13501-1, and avoid panels with high plastic content in their cores. When it comes to fire safety, cutting corners is simply not an option. By staying informed and vigilant, you can help safeguard your building, its occupants, and the broader community from the devastating consequences of fire.

Stay informed. Stay safe. Ensure your ACP panels are truly fire-resistant.